The industrial hose is vital for the seamless transportation of fluids. The Mingqi PVC Steel Wire Reinforced Hose emerges as a premier solution, expertly crafted to meet the stringent requirements of diverse industrial applications. Manufactured in Shandong, China, this hose epitomizes the blend of strength, flexibility, and reliability that is essential for demanding industrial environments.

Steel Wire Reinforcement

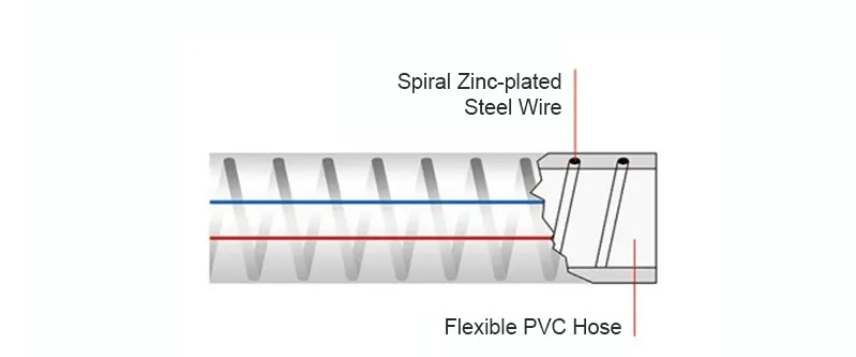

At the core of the Mingqi hose is its exceptional material composition. Constructed from top-tier PVC (Polyvinyl Chloride) and fortified with steel wire, the hose offers an optimal balance of durability and flexibility. PVC is renowned for its resistance to abrasion, harsh weather conditions, and a wide array of chemicals, making it an ideal choice for industrial use.

Working Pressure

Performance is where the Goldsione hose truly excels. Designed to operate at a working pressure of 3-6 Bar, it meets the demands of moderate pressure applications, making it suitable for a wide range of industrial uses. Its operational temperature range of -10°C to 65°C ensures reliable performance across various climatic conditions, making it a versatile choice for both hot and cold environments. This broad temperature tolerance guarantees that the hose remains functional and efficient regardless of external conditions.

ISO Certificate

The PVC Steel Wire Reinforced Hose is certified with the ISO Certificate, reflecting its adherence to international quality and safety standards. This certification provides assurance to users that the hose is manufactured to the highest standards and is safe for use in industrial applications. Compliance with these standards is a testament to the hose’s superior quality and reliability.

Broad Applications

In terms of application, the Mingqi hose is remarkably versatile. It is designed to excel in environments where fluid transfer is critical, such as in the transport of oil, water, and various chemicals. Its robust construction enables it to withstand harsh industrial conditions, including exposure to chemicals and abrasive materials. This durability translates into a longer service life, reducing the need for frequent replacements and thereby offering cost savings and operational efficiency.

Post time: Jul-06-2024